Built by Listening. Fueled by Craft. Driven by Care.

LitUp didn’t start with a master plan, a corporate roadmap, or a desire to chase market share. It started with curiosity, technical instinct, and a willingness to listen — really listen — to the people using the product. What exists today is the result of hands-on problem solving, real-world feedback, and a belief that cannabis works best when it’s treated like a craft instead of a commodity.

Before Cannabis, There Was Heat and Air

For more than 30 years, LitUp’s founder worked with gases, pressures, and temperature systems while learning how to move materials safely, cleanly, and efficiently. When he stepped into cannabis extraction, the principles felt familiar.

“People don’t realize it, but extraction and HVAC work on the same fundamentals,” he explains. “You’re controlling pressure, changing states, moving from liquid to gas and back again. Once you understand that, everything clicks.”

That understanding became the backbone of LitUp’s extraction process. Early on, he walked into a facility where things weren’t working right — oil coming out dark, inconsistent results, no clear explanation why. Within a day, he had diagnosed the issue.

“The pressures were wrong,” he says simply. “Once I corrected that and changed the approach, everything cleaned up.”

That moment didn’t just change the product — it changed the direction of the business.

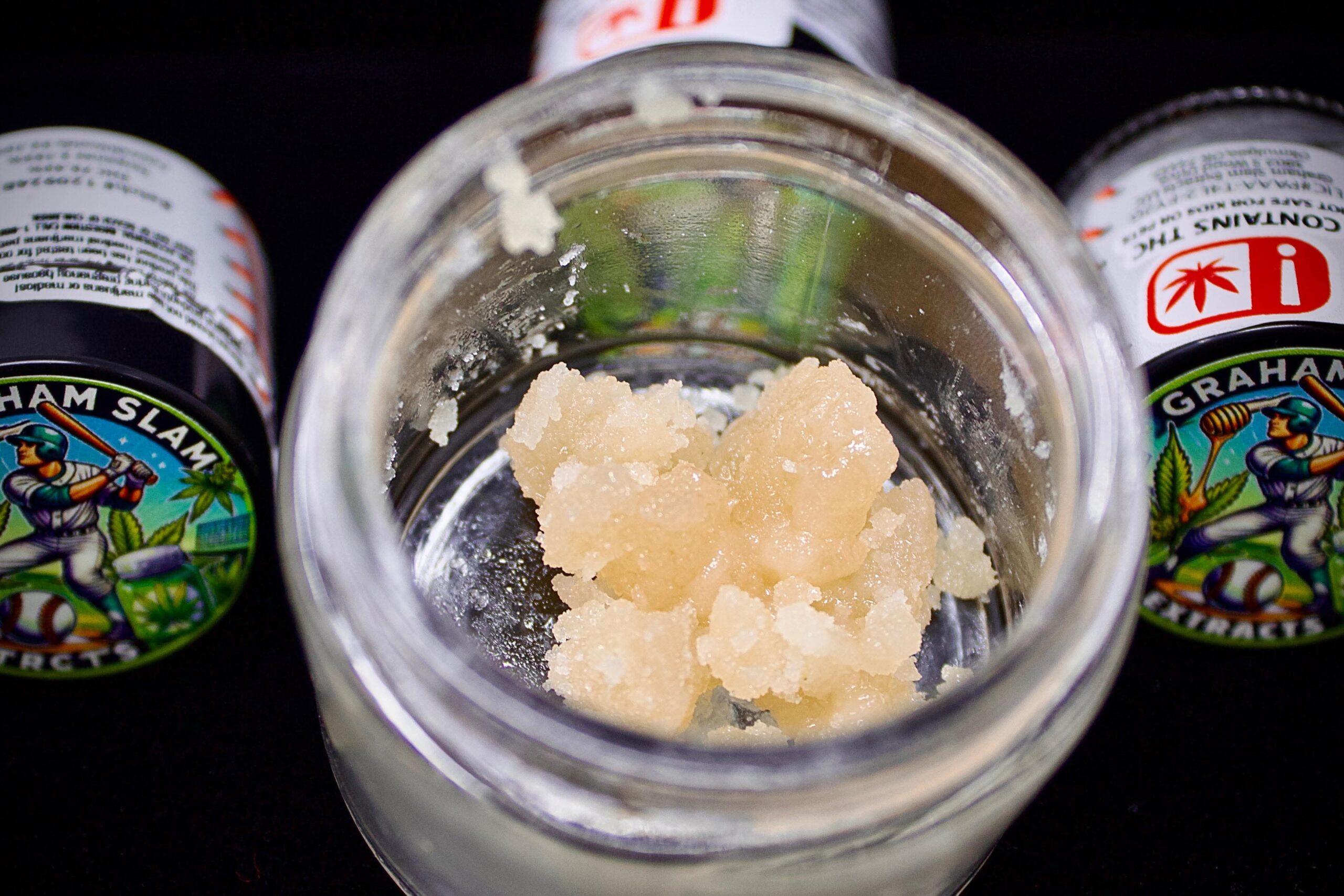

Cleaner Inputs. Tighter Control.

LitUp made a conscious decision early on to prioritize cleaner inputs and tighter control. Instead of blending solvents for speed, the process shifted toward purer butane, lower pressure, and slower refinement. The result: cleaner oil, easier solvent recovery, and more consistent terpene retention.

“It’s not about shortcuts,” he says. “It’s about controlling every stage.”

The goal is simple: pull the good stuff, leave the rest behind.

Built From Feedback

LitUp products aren’t built in isolation. “They tell me what they want, and I do it,” he says. “Budtenders, customers, dispensaries — I ask them straight up.”

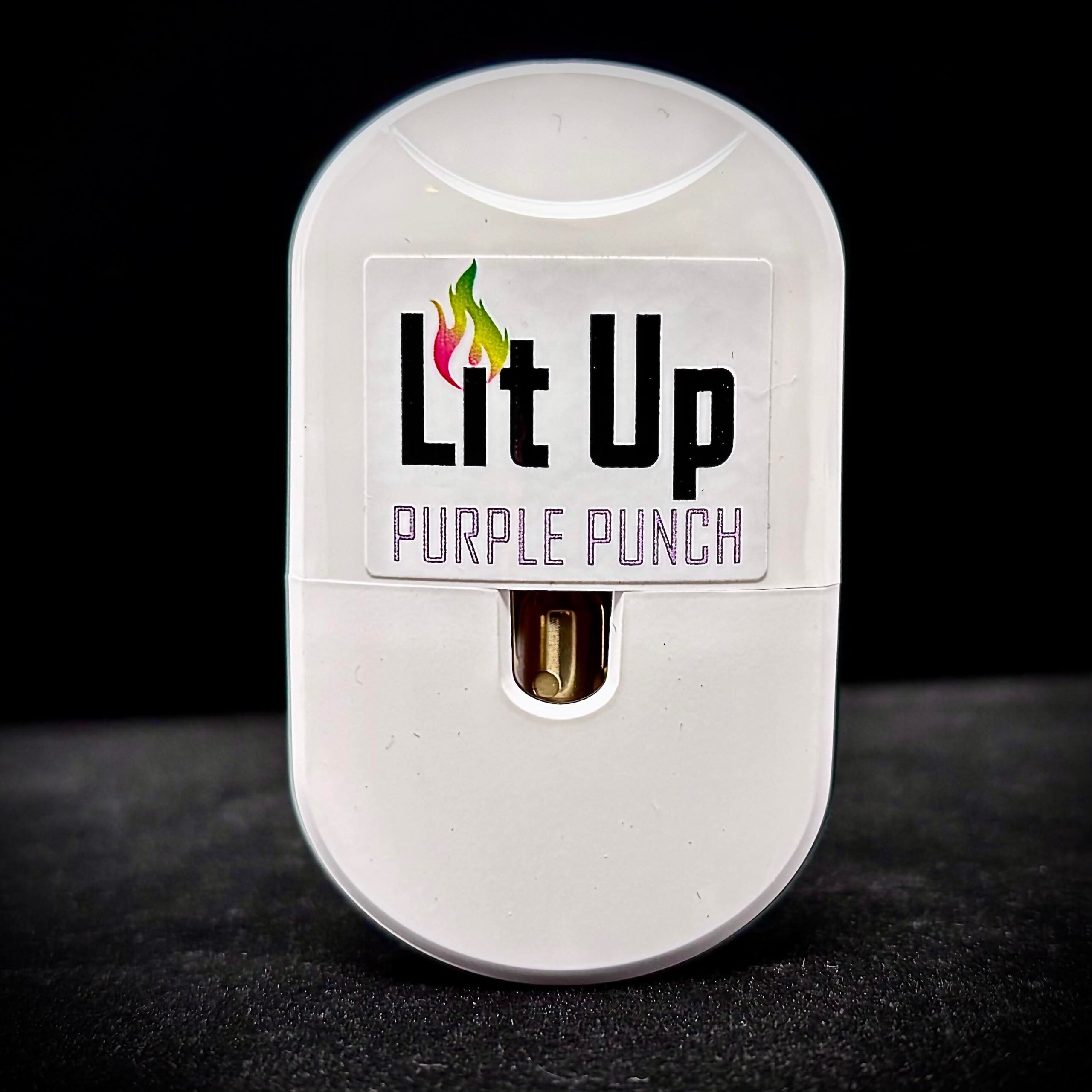

One of LitUp’s most successful product lines came directly from a dispensary conversation. A budtender mentioned that if dabs matched vape flavors, people would go crazy.

“So I tried it,” he says. “Brought samples back. She told me to roll with it. So I did.”

That same feedback loop shaped LitUp’s vape lineup. Multiple hardware options were tested side by side — filled, abused, overheated, flipped upside down — until one stood above the rest.

“It wasn’t the cheapest,” he admits. “But it didn’t leak, didn’t fail, and held up. That mattered more.”

Margins stayed thin — sometimes razor thin — but trust grew fast.

Terpenes Over Hype

LitUp’s vapes stand apart because of where the terpenes land, not how loudly they’re marketed. While many products struggle to break moderate terpene percentages, LitUp routinely clears higher thresholds — without additives, without gimmicks.

“The THC is still there,” he explains. “But people want flavor. They want the experience.”

Rather than chasing inflated numbers, LitUp focuses on balance, taste, and repeatability — products that feel good and keep people coming back.

Craft With Capability

LitUp doesn’t mass-produce and hope it sells. Production is largely order-driven, especially for flower and dabs. Products are packaged fresh, close to delivery, and moved quickly.

“I don’t want stuff sitting on shelves for weeks,” he says. “It’s craft. It should feel that way.”

Even with that approach, the facility can produce up to 2,000 units a day when needed — proof that craft and capability don’t have to cancel each other out.

Stacking Intentionally

LitUp isn’t slowing down. They are just stacking intentionally.

- All-flower pre-rolls (no trim, no filler)

- Live products

- Solventless offerings

- Expanded distribution across Oklahoma

“I’m interested in multi-state,” he says. “But not if it kills what makes this special.”

LitUp doesn’t try to outspend or out-shout larger brands. “I know I can’t beat them,” he says. “So I don’t try.”

Instead, the focus stays on people — dispensaries, patients, customers.

“We deliver seven days a week. Middle of the night if we have to. If someone’s running low, we get it to them.”

That commitment isn’t delegated. He does the deliveries himself.

“Make me work,” he laughs.

Sunshine in the Foundation

Behind LitUp is a story of encouragement, loss, and legacy.

Karli, known to many as Sunshine, was a passionate advocate for cannabis education and patient care. She spent years as a budtender, taking classes, learning strains, and helping people understand how cannabis could improve their quality of life.

“She wanted this to be pure,” he says. “Caring. Loving. For everyone.”

It was Karli who encouraged him to step into the industry. She believed in him before the business existed. She passed away shortly after, but her influence remains embedded in the way LitUp operates.

“She was sunshine,” those closest to her say. “Every day. No matter what.”

LitUp isn’t built on hype. It’s built on listening, learning, adjusting, and showing up — every day — for whoever needs it. And when you see the logo, that’s what it stands for.